Control, Connection and System Control Settings of CNC Control Units

CNC control units, also called "Computer Aided Numerical Control" in Turkish, have different types for different needs. Throughout the article, we will try to answer the question 'How to control CNC control units?', which is one of the most frequently asked questions about CNC control units. Then, we will give information about the connection and system control settings in the CNC control panels. We hope it will be a useful article for you and we wish you a pleasant reading.

Details About CNC Control Unit

The control mechanism uses the latest industrial and high-speed ARM processor. Since the structure of the machine is more compact and usable, the stability and reliability of the system is complete. Real-time high speed control can be provided. The system was developed based on lathes. It has 3, 4, 5, 6, 7 and 8 axis connections. The full-screen English menu view helps you move forward with your operations quickly and simply.Meanings of CNC Control Panel

CNC lathe has highly effective automatic material. This product with the ideal system not only promises to perform the work to be done in high quality, but also makes the functions of the lathe fully usable and applicable. For this reason, programming is very important. In this section, the directions of the CNC control panel program will be introduced.Basic Concepts of CNC Control Panel

The main concepts you need to know before using the CNC machine will be listed in this section.• Program Segment: It is the command line consisting of instruction and data parts.

• Program: It is the place where the machine-related part of the workpiece is completed.

• Machine Coordinate System: It is the system itself that coordinates the machine.

• Working Coordinate System: It is the work coordination system. It is installed by CNC. The coordinate system may change to activate the zero point.

• Local Coordinate System: This setting should be turned on for easier programming when programming in the 'Workpiece Coordinate System'.

• Absolute Programming: Confirms the exact coordinate system.

• Relative Programming: It is related to the direction of the operation and its distance to the end point.

• The Maximum Programming Unit: Maximum programming unit => 0.001mm

• Mode Instruction: Method instruction. This instruction ensures that the function remains in the program.

• Suspending Mode: This part is used to suspend the job and restart the job.

• None-Mode Instruction: This instruction has no function. It only works in the program segment.

CNC Control Unit Programming

• ‘’-‘’ means the data is available.• '0' indicates that the data processes only effective/useful data.

CNC Control Unit Program Instruction

In this section, all functions will be introduced accompanied by codes.• N => It is the number of the program segment. | Data range => 0000-9999

• G => Type of specified instruction operation | Given range => 00-99

• M => Auxiliary operation instruction | Data range => 00-99

• THD => Indicates the number of the Vehicle/Tool | Data range => 0-99999

• S => Speed of first lathe spindle | 0-99999

• SS => Speed of second lathe spindle | 0-99999

• F => Cuts speed once per minute | 0.01 – 15,000mm/min

• X, Y, Z, A, B, C, Xs, Ys => The axis of the Ys value and the coordinate values of the others are | 99999.999mm

• R => Circular arc radius | 0.001-99999.999mm

• PX => GO4's delay time | 0.001-65s

• P => Indicator for entering the started program | 0000-9999

• L => Times of the cycle | 1-9999

• / => When this indicator appears on the program line, the operation should not be performed.

Programming Layout of CNC Control Panel

We can list the main things to know about the programming layout of the CNC control panel as follows:• Multiple instructions can be given on one line.

• Instructions and parameters can be placed randomly on a line.

• The instruction cannot be repeated on the same program line.

• An independent parameter and instructed operation cannot appear in the same program line.

• '0' cannot be written in front of the instruction code.

• The instruction behind any starting point, point, line, or change must use the complete program.

• Non-mode instruction must be used in the specified program line. The mod instruction always takes effect before another similar instruction appears.

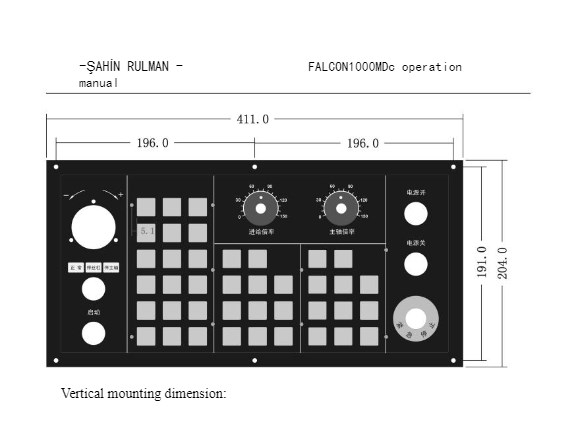

Connection and System Control Settings in CNC Control Panels

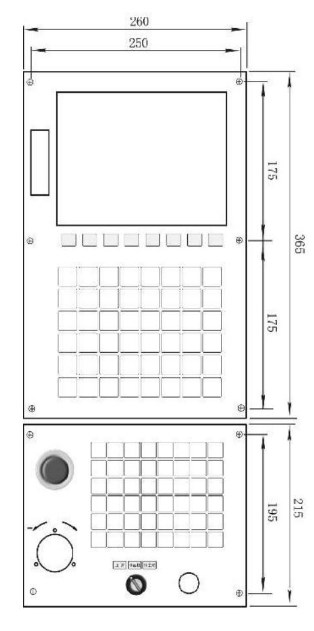

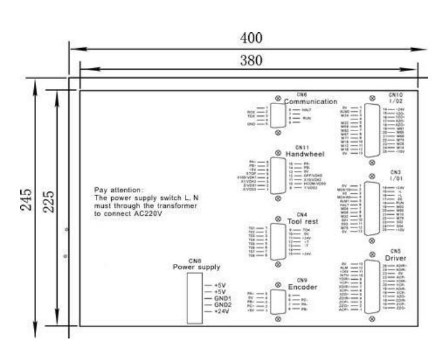

After providing information about the control of CNC control units, we can provide visually supported information about the connection and system control settings in CNC control panels.

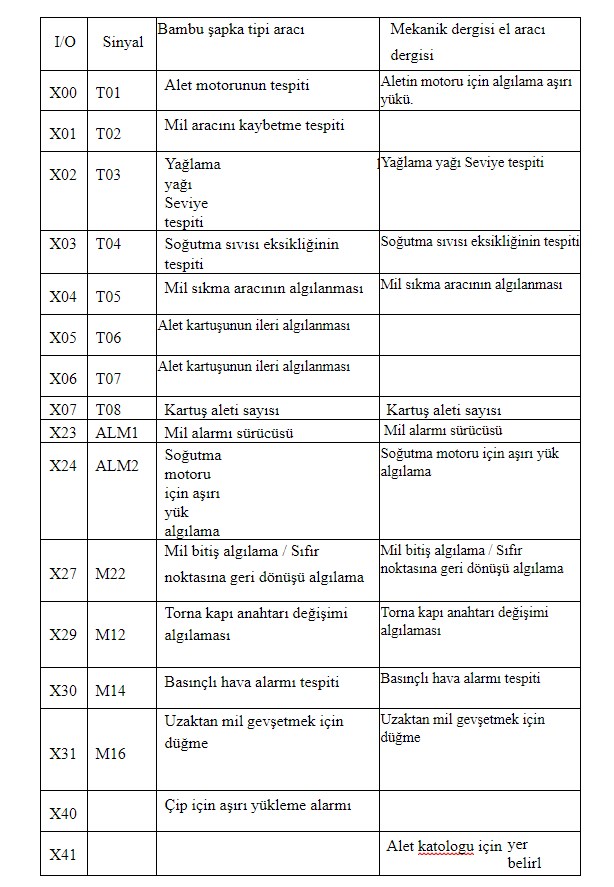

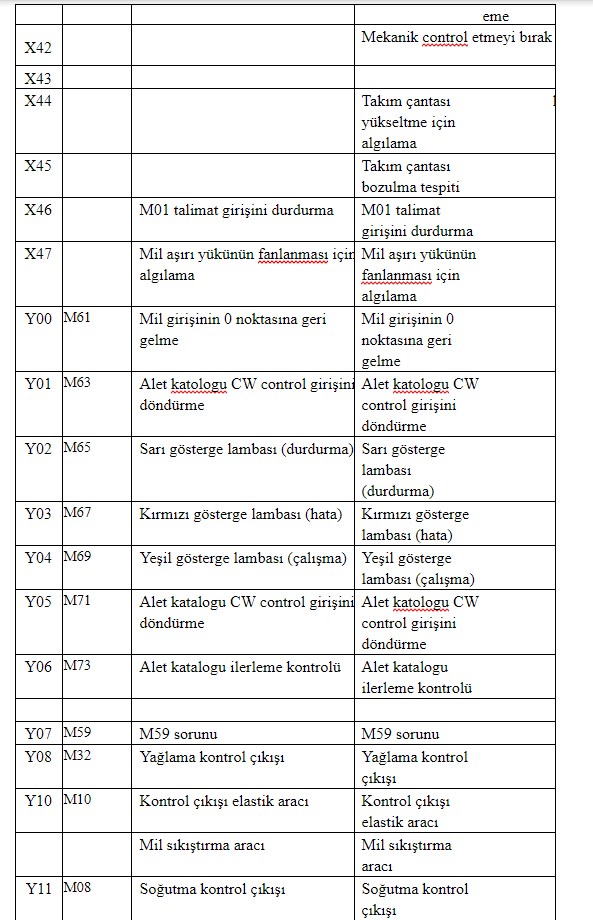

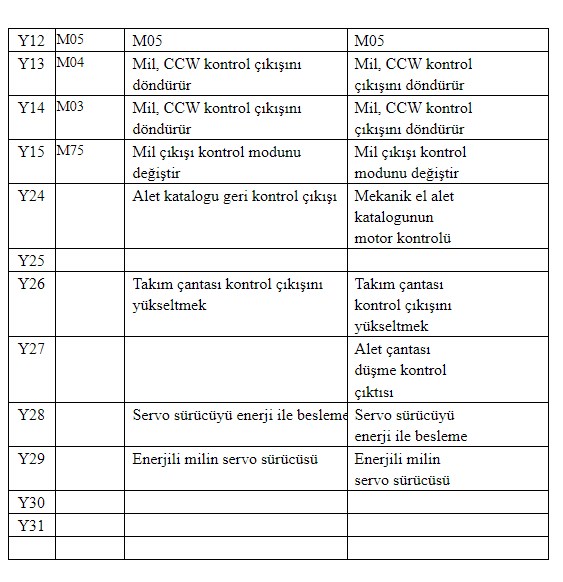

Explanations of Tables in the Operating Instructions of CNC Control Panels